The ideal room environment is not only good for comfort it is essential to guard against damage to expensive furniture, documents or sensitive equipment. The effects of moisture damage, whether it be mould, mildew or corrosion can be costly, inconvenient or even catastrophic.

The two primary concerns of climate control are temperature and humidity.

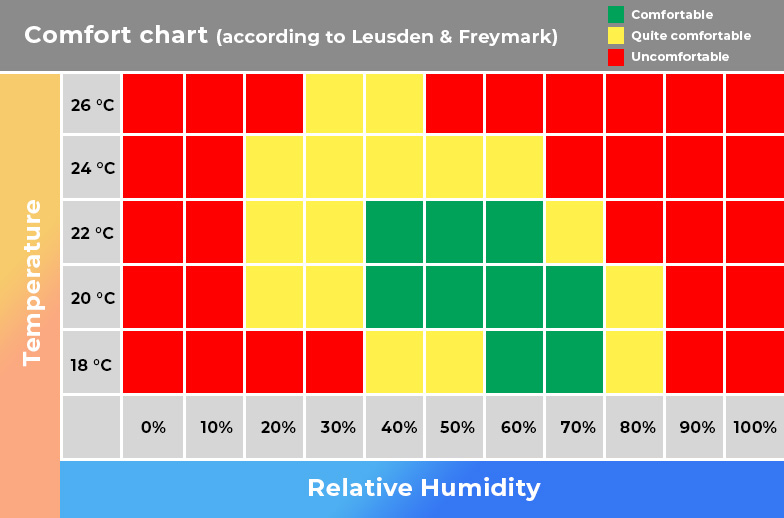

If we look at the Leusden and Freymark illustration below the optimum conditions for human comfort are between 20-22°C with an RH (relative humidity) level of 40-60%. Anything beyond these parameters starts to feel uncomfortable.

In day to day life it’s the RH level that causes most issues and often the first we know about it is the signature musty smell, a damp patch or speckled mould on a wall. Rust can form at just 60% RH and mould from 70% so you can see the importance of keeping moisture in check.

Left unchecked a rooms RH level will fluctuate wildly as climactic conditions vary, and it rarely reaches an optimum level without mechanical intervention.

The Benefit of Theory

An informed choice is a better choice. A quick swot up on the basics of humidity will help you make the best choice for your application when it comes to purchasing a unit.

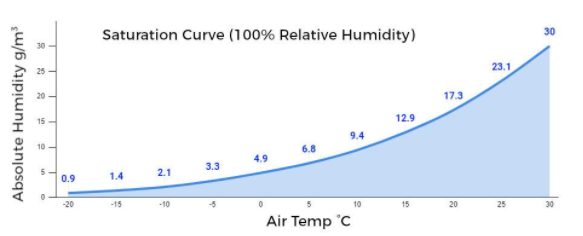

Air has ‘dew point’ or saturation point which represents the maximum amount of vapor it can absorb absolutely. This is known as absolute humidity and it’s measured in grams of water per cubic meter of air.

With dehumidification you use the amount of water that is actually dissolved in the air and compare it to the maximum amount of vapor it could absorb at whatever temperature the room is, thus giving you the Relative Humidity, or RH level as it is more commonly known.

For example, if you have a room with an RH level of 50% then the air within it has half the amount of vapor it could hold at whatever temperature it is.

Temperature

The capacity of air to absorb water is directly related to the ambient temperature; the lower the temperature the less water it can absorb and the higher it is the more it can. Below you’ll see a table we’ve put together to help illustrate the relationship between air temperature and the amount of water it can hold. Below that there’s a further table that uses five different temperatures to show how it influences the absorption capability.

Water vapour content of air:

At 25°C, 1M3 of air can absorb a maximum 23g of water which would be a humidity level of 100%.

If however the air was just 10°C, say thanks to contact with a cold medium (like a window surface) then the maximum amount of vapour it can absorb reduces to 9.4g. That extra 13.6g of water then condenses onto the colder surface.

| Influence of the room temperature on the water absorption capacity of the room air

| ||||||

| Room temperature

| 25 °C

| 20 °C

| 15 °C

| 10 °C

| 5 °C

| |

| Example 1

Constant relative humidity

| Relative humidity

| 80 %

| 80 %

| 80 %

| 80 %

| 80 %

|

| Water content of the room air

| 18.4 g/m³

| 13.8 g/m³

| 10.2 g/m³

| 7.5 g/m³

| 5.4 g/m³

| |

| Example 2

Constant water content

| Water content of the room air

| 5.4 g/m³

| 5.4 g/m³

| 5.4 g/m³

| 5.4 g/m³

| 5.4 g/m³

|

| Relative humidity

| 23.5 %

| 31.3 %

| 42.1 %

| 57.5 %

| 80 %

| |

Example 1 shows what happens to the water content as the temperature falls but the RH level maintains a constant 80%. You’ll see the corresponding water content varies massively as the temperature decreases.

Example 2 maintains a constant water content within the air while the temperature decreases, thus increasing the RH level.

Now, hands up, we admit that was lost on us too, but we’re trying to be thorough. However, unfortunately, things get even more complicated when you’re dealing with perishable materials and have to allow for corrosion, decomposition or mould. In these circumstances it’s relative humidity you should concern yourself with and not absolute, as that will have little to no bearing.

The Relevance of Relative

To help simplify things we’ll look at example 2 in the table above. Here you can see that at 5°C with a moisture content of 5.4g/m3 the RH level would be 80%, which is the threshold for metal corrosion and way over the level for mould formation. However at 25°C the RH level would be just 23.5%, which although far to dry to be comfortable for human habitation as it affect the respiratory system, wouldn’t be ‘damp’ enough to allow mold or rust to form either, even though the absolute moisture content of the air was still 5.4g/m3.

As we can see, if your looking to control condensation or then it’s the relative humidity level that needs to be dealt with. Trying to reduce the overall amount of moisture in the air is folly, just concentrate on the RH level. Once you understand this then you’ll be in a better position to source the appropriate dehumidifier.

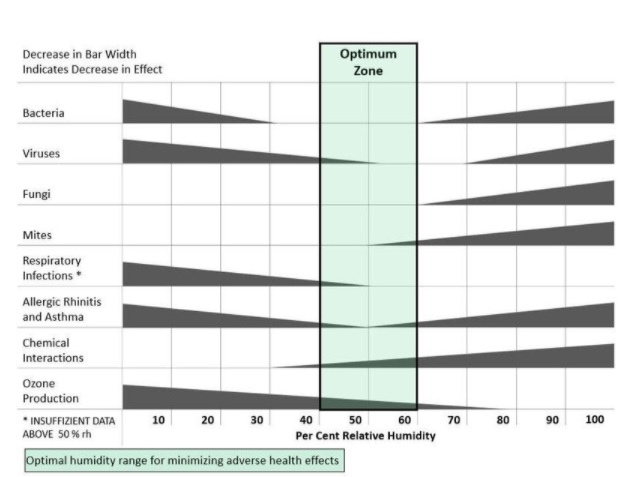

How Relative Humidity Affects Human Health

Active vs Passive Dehumidification

The picture above shows a typical refill for a dehumidifier. The pouch will contain granules of a hydroscopic material like calcium chloride which will absorb moisture using a process called desiccation.

Compared to electrical dehumidification which also heat the air before returning it to the room the cost/benefit ratios of passive dehumidification are extremely poor.

The main uses of passive dehumidification are those small silica gel packs found in new suitcases, clothing, medical supplies and electronic equipment.

The two main methods used to control excess humidity.

Before we delve deeper into this let’s dispel the common misconception that heat makes air drier. It doesn’t, it just makes it warmer.

As we can see in the previous section above warm air can absorb more vapor than cool air, so although raising the temperature of the air within an environment with a constant water content will reduce the relative humidity it doesn’t reduce the total amount of moisture in there.

As that air gets warmer and warmer and circulates within the room then the extra moisture just condenses on the cold surfaces of that room, so the overall moisture content of the room is just the same.

So, if you’re looking actually take moisture from the air the only real solution is mechanical dehumidification, be that via condensation (refrigeration) or desiccation. Not that heat isn’t used in effective dehumidification as we’ll find out below.

Condensation vs Desiccation

Refrigeration, condenser driers, or Peltier dehumidifiers all relay on creating condensation i.e. they create a cold surface over which they pass the air, when air hits that surface the moisture contained within it condenses before being collected and removed.

Desiccant dehumidification utilizes the hydroscopic, or moisture absorption properties, previously mentioned. However unlike passive dehumidification mechanical desiccant dehumidification also uses heat for a process known as hot air regeneration.

See our full range of dehumidifiers here or contact us now.

What’s in a name?

I’ll need to ask forgiveness from the marketing department for this one, but if we cut through all the bluster, all the fancy names and all the various claims about mechanical dehumidifiers in essence they all do exactly the same thing; draw air in using a fan then pass it over something to remove the moisture. They then warm the air slightly and return it to the room where it recirculates. This happens continuously until the desired RH level (if you’re using a humidistat) has been reached.

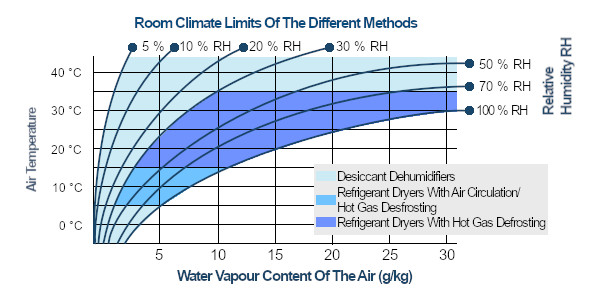

However, what is true is that because of the different methods they use to extract that moisture the desiccant and refrigeration dehumidification processes are better suited to different applications.

Refrigeration/condensation

As shown in the saturation curve at the start of this, the capacity of air to absorb moisture is entirely dictated by the temperature; the lower the temperature the less it can hold, the higher it is the more it can.

When air cools quickly e.g. when it comes into contact with a cold surface, it exceeds dew point (100% RH) and the excess moisture condenses into water on the cold surface as condensation.

Let off some steam (Bennett?)

You’ll perhaps be more familiar with the process of condensation and ‘dew point’ than the 30 year old Arnie reference above: Cold beer on a hot day? The bathroom mirror after a warm shower? What do both of these scenarios have in common? Yep, condensation. Both the moisture on the outside of your beer bottle and on the mirror are common examples of dew point being reached quickly thanks to contact with a cold surface.

Other common examples of vapor heavy air cooling below dew point include car windows misting up, early morning mist and people cleaning their glasses.

So as air cools the less moisture it can hold and any excess it contains will condense and it is this principle that’s used by refrigeration dehumidifiers to lower the moisture content of an environment. They suck air in via fan, then blow it across a cold surface, catch the condensate that forms and return the air to the room. Refrigerated dehumidifiers come in all shapes and sizes ranging from small, plastic units found in homes all the way up to large swimming pool dedicated types. The most common applications though are probably building sites where you’ll find mid range industrial dehumidifiers helping to dry out plaster etc.

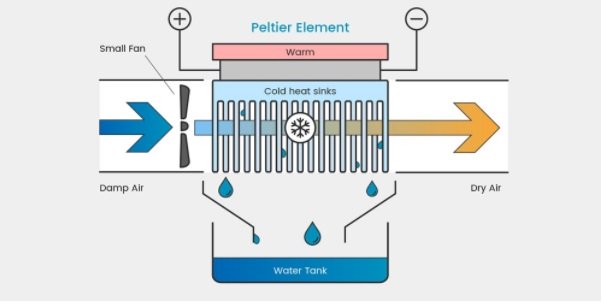

Right at the bottom end of the performance scale of electric dehumidifiers you’ll also find something called a Peltier dehumidifier.

A Peltier dehumidifier also use the process of condensation to remove moisture. We won’t dwell on these too much as they’re particularly good and although they don’t require much energy to run are dreadfully inefficient.

Instead of using the refrigeration to produce a cool surface these units use the Peltier effect. This is when an electric current is passed through bi-metallic semiconductor and results on one surface getting warm and the other cold. Now, although they might not use a nasty refrigerant (boo-hiss from the environmentally aware) and might claim low energy usage (although again, they’re not as efficient as refrigerated dehumidifiers and it can take up to four times the amount of energy to remove a litre of water) they’re just not very good and are therefore not used in any serious drying application.

Desiccation

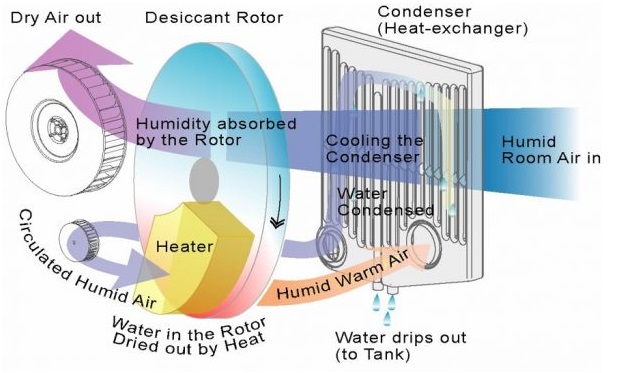

Unlike condensation dehumidifiers which use the dew point to remove moisture, desiccant dehumidifiers use something called sorption, which is the physical and chemical process of one substance becoming attached to another. In this process the vapor pressure gradient between the humid air and the desiccant substance being used. Sometimes you might also here the desiccant being called the hygroscopic sorption agent, but that doesn’t quite trip off the tongue as well as desiccant.

Because of the method used this category of dehumidification also includes silica gel packets etc, but these are pretty useless for anything other than small, sealed environments such as boxes.

Gel packets

Those small packets of silica gel that fall out of laptop boxes and you panic to make sure the kids or the cat can’t get to them? They’re the most basic and simple form of dehumidifier used today, utterly useless for anything much bigger than a shoe box or handbag but perfect for helping keep sensitive items safe.

Gel packets, just like the previously mentioned passive dehumidifiers should not be seen as a viable alternative to industrial dehumidifiers. They’re single use and require regularly replacing, uneconomical and have no way of circulation the air so cannot really effect the overall RH level of an entire room. Oh, and lets not forget they don’t exactly contain the most environmentally friendly substance and would have to be disposed of after being used.

So, although desiccant dehumidifiers will also use something like silica gel because of it’s excellent hygroscopic sorption abilities, where it differs from the little packets mentioned above is that they will employ heat to regenerate the silica. In lay mans terms that just means its good at absorbing moisture vapor and a desiccant dehumidifier will dry it out so it can be continuously used.

A desiccant dehumidifier will have a wheel coated with something like silica gel or lithium chloride that gently rotates, while a fan draws in air from the room and passes it across through the wheel. As the air comes into contact with the hygroscopic material the water vapour is absorbed and the drier air is returned to the room.

Now, because those hygroscopic materials can only absorb so much moisture before they become saturated and ineffective, desiccant dehumidifiers use thermal energy to regenerate (dry out) the silica or lithium chloride. This way the unit can maintain effectiveness instead of quickly becoming saturated.

Common condensation

Condensation is a pretty common occurrence and in fact you’d be hard pressed to go through a day without encountering it. From morning dew to steamy car windows whenever damp air comes into contact with a cooler environment or surface the moisture within it will condense, and this is the principle on which refrigerant dehumidifiers work.

Cat litter is perhaps the most well known use of hygroscopic material, as it soaks up moisture and humidity and but quickly becomes saturated so must be regularly changed. Desiccant dehumidifiers avoid this by ‘recharging’ the desiccant material using thermal energy.

The different types of condenser dehumidifiers

The refrigerant drier is by far the most common type of dehumidifier in the building, rental and hire industries as, well as domestic applications. Why? Well that’s because in short they’re the most effective for that sort of application. The environments within homes, shops, offices, etc tend to be around 12 – 25°C, which is a sweet spot when it comes to the cost/effectiveness/efficiency ratio of this type of drier. They’re not as expensive as desiccant units but much more effective than peltier driers so are particularly well suited to these kind of applications.

How it works

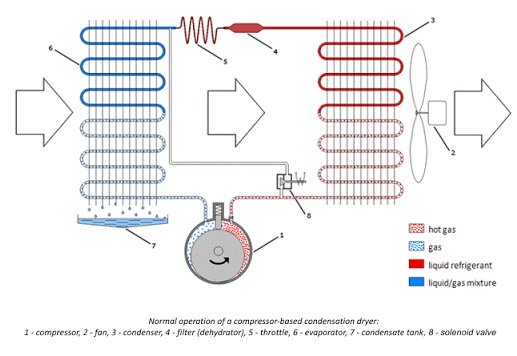

As we’ve covered elsewhere on the site, a refrigeration system works by pumping a substance with a very low boiling point around a sealed circuit containing components that increase and decrease the pressure. As the substance (aka the refrigerant) moves from the capilliary, which restricts the flow and increases the pressure, into the evaporator it cools quickly to a temperature well below the ambient room temperature. In doing so it makes the surfaces of the evaporator cold enough to bring the air flowing over it quickly below dew point.

As we know from above, once air cools below dew point it reduces the amount of vapour it can hold this excess moisture condenses onto the cold surface, in this case the evaporator coil. As the water builds up it runs down the fins of the evaporator into a collection device.

The other side to a refrigerant system is the condenser which is where the refrigerant condenses and releases thermal energy in the form of heat. After the air has passed over the evaporator coil it is passed over the condenser to be warmed to increase the amount of water it can hold, before being returned to the room as warm, dry air to collect more moisture.

Ice Ice baby

If the dehumidifier is operating at an ambient below about 15°C the moisture forming on the evaporator will freeze as it condenses, then as the ice builds up it reduces the effectiveness of the unit. To counter this most refrigeration dehumidifiers will have a regular defrost mechanism that kicks in periodically to melt any ice that might have built up on the coil. Without this and if left unattended the evaporator might completely lock out with ice preventing airflow and even possible damage to the coil.

The most common form of defrost mechanism is hot gas bypass, where a timer within the unit will activate a valve in the circuit to divert the warm refrigerant on its way to the condenser straight through the evaporator instead. The effect of the hot gas is to melt any ice on the evaporator so that it runs down into the condensate collection device (bucket). After a few seconds the valve closes and the system reverts to normal.

In more detail

This diagram shows the schematic layout of a typical dehumidifier featuring a hot gas bypass circuit and names the major components.

Air Circulation Defrost

Running the unit in an environment above about 15°C? Then it’s warm enough to use an air circulation defrost system. You might also know this as electronic defrosting as it uses a sensor to monitor the ice build up on the evaporator.

With this method when the ice reaches a certain point the sensor switches off the compressor but keeps the fan going. As the refrigerant is no longer getting cold in the evaporator the warm air drawn across the system by the fan melts the ice, hence the need for a fairly warm ambient.

Although this system can work well in warm climates when the environmental temperature drops below about 15°C the surface temperature of the evaporator coils falls below 0°C and the ice formation becomes quicker and more aggressive, meaning the sensor has the unit in defrost almost permanently.

In these circumstances dehumidifiers with electronic or air circulation defrost systems are pretty useless as they spend more time in defrost than they do dehumidifying!

So, unless you live somewhere with a mild to warm climate you’ll probably be better served with a refrigerant drier using a hot gas defrost rather than an air circulation type.

Hot gas defrost

The vast majority or portable dehumidifiers utilize the hot gas defrost method of ice removal, not only is a more effective system it can be used at lower temperatures and can therefore be left unattended, which might come in useful if you have anu application that needs the unit to be left running overnight or in winter. One of the most popular uses for industrial dehumidifiers is on building site where it can get pretty cold during the winter months even with doors and windows in but without the heating yet plumbed in, with this in mind most portable dehumidifier manufacturers will have a hot gas defrost in their systems.

As detailed above, with this type of defrost circuit a timer regularly opens a solenoid valve that redirects the hot refrigerant directly into the evaporator coil rather than the condenser. Once in the evaporator the refrigerant melts the ice and continues being circulated by the compressor. After a shirt time the timer closes the valve and the system returns to running normally with rapidly cooling refrigerant in the evaporator.

Defrosting using a hot gas mechanism is much faster and more effective than air circulation at lower temperatures so when you’ve got an application with an ambient below 15°C then this is the system to go for. If however you’re trying to dry out an area and the temperature is above 15°C then the difference between the two systems is minimal.

See our full range of dehumidifiers here or contact us now.

In conclusion

Dehumidifiers with hot gas defrost are great all rounders suitable for most applications (especially here in the UK) where seasonal or even daily temperature fluctuations are a consideration, as you can get the most out of them across a wider temperature range than air defrost systems. This means that they’ll perform well in colder rooms such as cellars and across the seasonal spectrum. If however the application you’re looking at stays between 15-35°C then an air defrost system might be a viable alternative.

The poor relation

As we’ve already mentioned there is another type of dehumidifier that uses condensation to extract moisture from the air, but it doesn’t use refrigeration to create a cold surface. Peltier dehumidifiers, also known as electric or semi conductor dehumidifiers, use a type of semiconductor called a thermoelectric cooler or TEC for short to generate a cool face for the air to pass over.

The peltier effect dictates that when you pass a current through two joined conductors it will take heat from one side, thus creating a cold face and transfer it to the other side, creating a hot surface. The temperature difference between these two faces or plates can be as much as 70°C. A small fan draws air across the cool side whereupon condensation forms, drains away and is collected in a suitable receptacle.

Peltier conductors are small, neat and compact so the dehumidifiers are much smaller than the other types, plus as they don’t use compressors or heating elements and only very small fans the electrical consumption of Peltier driers is a fraction of that used by refrigeration dehumidifiers. Thanks to all of this they’re also commonly found in camping coolers, small fridges and inside PC’s as well as dehumidifiers of course!

In order to extract moisture from the air a fan draws air in from the room, passes first across the cold side of the conductor and then over the warm side. The cold side cools the air below dew point reducing the amount of moisture it can hold and the excess condenses onto the face of plate, before the fan then passes it across the warm side where its heated and returned to the room as warm’ dry air.

Unlike a refrigerant, peltier elements don’t need a defrost mechanism as the plates never get cold enough to freeze up. Another bonus to them is they are very quiet in comparison as there’s no compressor and only a small fan that doesn’t move large quantities of air.

There is, however, a pretty large downside to the Peltier driers though; they only have a very narrow operating range and low efficiency (a big no no these days). When compared to their refrigerated cousins semiconductor driers offer a poultry 25% efficiency, so they really aren’t a viable alternative for anything other than very small applications.

To get the same sort of performance from a semiconductor dehumidifier as you would from the other types mentioned, say 10l-20l per 24 hours, you’d need to have 40-80 Peltier elements operating parallel in a single unit. Not only would that increase the size of the unit to something totally unmanageable, it would also send the energy consumption through the roof.

Finally, and again the marketing department aren’t going to like this, but you might see when you see semi conductor driers rated in litres per kWh. If you do come across this be warned that it isn’t an accurate way to compare to compare them to other types of dehumidifier. Peltier technology is not easily scalable and cannot practically achieve the results of refrigeration or electric desiccant dehumidification. Despite what the figures lead you to believe the reality is that they will only produce an average amount equivalent to a small glass of water, somewhere in the region of 100-200ml.

So, to surmise, dehumidifiers that use Peltier elements or semiconductors as their extraction method are OK for small rooms and cupboards such as pantries, closets or under the stairs but aren’t really any good in most rooms…despite what the website tells you.

Desiccant dehumidifiers: The big boys.

If you’re looking for something to extract large volumes of moisture, operate in low humidity or at a low temperature then it’s a desiccant dehumidifier you’ll need. At the more specialist end of the dehumidifier spectrum, desiccants are big, expensive and therefore usually reserved for large commercial or industrial applications where results outweigh costs more so than they would on for an everyday job.

Because of what they are and where they usually find themselves i.e. without the need to worry about noise or comfort, desiccants tend to be built for resilience and a high airflow rate. Because they process such large volumes of air the moisture they extract is despatched from the unit as warm vapour instead so it can be ducted away at a faster rate, just like the exhaust on a tumble drier.

None of this is to say domestic desiccants don’t exist, some ranges do carry smaller models for use within the home, but when selecting your unit please bear in mind the industrial ones don’t come with any sort of collection vessel and will need to exhaust the vapour somewhere.

Built for comfort

These smaller domestic desiccant units still utilise the same method of extraction, but they also use a condenser device to help collect the water rather than just blow it down a pipe.

As with the commercial units, moist air from the room is drawn into the unit by a fan and blown across a rotating wheel. As previously covered this wheel will features a hygroscopic material that draws the moisture from the air as it passes, leaving the air dry but the material saturated.

As the wheel rotates the hygroscopic media passes through a separate isolated chamber where air is heated so the moisture passes back from the wheel to the air and is exhausted away. However, on the comfort devices rather than simply be exhausted away the warm, moist air is passed over a cooling condenser element where condensation collects and drains into a container.

Which dehumidifier is right for your application?

If you’re looking for a dehumidifier then there are four main considerations to take into account:

1) Room temperature.

If you’re looking for high performance in cooler areas such as cellars or garages, in fact anywhere you need to use it for prolonged periods below 8°C, then we’d probably recommend looking at either a desiccant dehumidifier or a refrigeration dehumidifier used in conjunction with a fan heater. The characteristics of desiccated units are much better suited to low temperature operation and will ensure continued operation well below that of a refrigerated unit.

Desiccated units are expensive though and if this is prohibitive you might be able to use a refrigerated unit with fan heater. Most fan heaters these days, such as our FF range, come with thermostats so you can set them come on if the room drops below a certain temperature. The performance might be as good as the desiccant but this might be a possible alternative if desiccants are a bit more than you’d like to pay.

On the other hand though, if you’ve got an environment where it’s regularly above 12°C then desiccants might not be the answer. Although they’ll still extract moisture above this temperature they become less and less efficient up to a point where it doesn’t really make economic sense to carry on using them.

Now, if you’re looking to extract moisture form the air within an environment with a less stable ambient, where the temperature has big swings and can fluctuate between, say, 5°C-35°C then it might be wise to opt for a refrigerated unit.

Although performance might tail off at the extreme ends of that performance envelope, they do offer a good general performance across a very broad range of conditions, certainly much wider than desiccant units. One thing to be aware of though is that if you’re using this type of machine regularly below 15°C then you’ll definitely want one with a hot gas defrost mechanism, as we covered earlier.

These good old machines are great all rounders, reliable, cheaper than desiccants and offer more consistent performance across a wider range of applications and if your application stays above that 15°C threshold then you’ll be fine with an air circulation defrost system.

2) Operating costs

When weighing up the ROI and cost/benefit ratio of different types of dehumidifier then it’s hard to look past a refrigerated unit. They’re relatively cheap and provide a good power consumption/extraction rate.

Peltier dehumidifiers might look cheap when it comes to the initial outlay and running costs but there very limited in performance. In fact, when if you compare their performance to some of the other types you’ll see they can use up to 400% more energy when extracting one litre of water.

Desiccant dehumidifiers will use up to twice the energy of the refrigerated type so can again be expensive to run. However, because of their unique and specific characteristics then there are times when only a desiccant will achieve the desired effect and therefore running costs are not the primary concern.

3) Size matters

The volume of air that needs drying is a big factor and, in general, the bigger the room the better suited a refrigerant drier will be. Why? Well that’s because they come in the biggest range of sizes, extraction capacities, airflow rates and are arguably the most versatile.

When calculating which dehumidifier is best for your application just must remember to take into account the airflow rates of units rather than just extraction rates. Extraction rates are based on an ideal set of conditions where performance is maximised (just like fuel efficiency on cars) and in truth are rarely ever achieved in real world conditions (again, just like the MPG figure your cars manufacturer quotes). Now, while there is some logic in thinking the higher the extraction rate is the better it will be for my large room, please bear in mind that you’ll also need a greater airflow rate. It’s all fine and well having the most powerful unit on the market but if it’s only got a tiny airflow it will only really be processing the same bit of air over and over, and have negligible effect at the other end of the room, so please remember the more powerful the unit the greater the airflow should be.

Finally, please disregard any ‘watts per litre’ figures quoted the manufacturer (ahem, marketing department). Accurate extraction rates are unique to each and every application, notoriously difficult to estimate and will vary from day to day, so these figures will also be based on the same ideal conditions mentioned above. If you are looking for a dehumidifier then you’d be better off making your decision based on the airflow rate, power consumption and extraction rates to identify the most suitable unit.

One type we can probably rule out for any serious drying application is Peltier dehumidifiers. They’re not really designed for reducing the overall humidity of an entire room suffering from excess moisture, but rather smaller spaces such as closets, pantries, shoe cupboards and possibly something like a windowless toilet (but not one with a shower as they produce large quantities of airborne moisture). What makes them so good for these types of environments is the silent operation and low power consumption, so you can leave them running and just let them get on with things and whereas they’re not great for eliminating problem condensation in an entire house, they’ll easily help with the moisture in a pair of shoes that’s been worn all day (and therefore help limit the associated ‘aroma’).

Another type of desiccant dehumidifier is granules, such as silica gel packs. Although primarily used to help protect sensitive goods such as IT equipment and also commonly found in shoeboxes, clothing and pharmaceutical equipment these little packets are technically dehumidifiers. Although a cheap method of helping keep moisture under control in very small spaces they’re utterly useless for anything else and should not be considered as a viable method of dehumidification.

That being said though there are types of dehumidifiers available that use larger packets of silica gel or similar, but again although they might have uses these are very limited and they are not to be considered a legitimate alternative to mechanical dehumidifiers. They cannot absorb much moisture, the area they can affect without a fan is tiny and once saturated the packets have to be dried out manually or replaced, making them a single use item.

Having covered every other type of dehumidifier we finally reach desiccants. If you need drying in a cold environment, temporarily heated space or already pretty dry environment they this is what you’ll need.

Although a powerful refrigerant unit will be effective down to 12°C, if the average ambient of your environment falls below circa 8°C then performance will start to tail off and the defrost mechanism might not be enough to cope with the ice build up. So, for any application with these sorts of temperatures you’ll need a desiccant dehumidifier as the method they use allows them to keep performing efficiently at temperatures way below a refrigerated unit.

4) Infiltration

Although this sounds like something from the world of espionage, in this context it actually refers to the additional moisture that creeps into a room from an external source or adjoining environment. This is unfortunately an inevitability, although not necessarily given appropriate consideration in most applications it is nonetheless an important factor to be taken into account in accurately selecting a dehumidifier, especially if the results are critical.

If your looking to dry the air within a certain environment and you’ve calculated what sort of extraction rate you think you’ll need, then please also remember that air from outside will ‘infiltrate’ the environment from outside. It’ll come in through doors opening and closing, around the edges of internal doors and possibly even through the walls and insulation depending on the buildings age and condition.

Imagine for a second that you’ve got a room where the ambient is 20°C and you want to reduce the RH level to 60% from 80%. At 80% the moisture content will be 13.8 g/m3 whereas at 60% it comes down to 10.4 g/m3 which means you’re looking to extract 3.4g of moisture per cubic meter of air.

For ease of maths let’s say the volume of air within our room is 100M3, so 3.4*100= 340g (or ml, it doesn’t matter) is what you need to extract, right? Sounds logical doesn’t it? But no, it’s not right because we haven’t taken into account the moisture in the external air that will seep into the room.

Right, now let’s assume the outside air is 25°C and 70% RH, which equates to 16.2 g/m3, 5.8g more that the air inside. Now, because nature abhors a vacuum the external air wants to mix with the internal air, however it can’t fully do that because of things like insulation, closed doors etc. To compensate for this when calculating accurate extraction requirements we use something called the infiltration factor.

We’ll say the room we’re trying to dry is well insulated and the infiltration factor of a well insulated environment is 0.3, so we can now calculate the following:

5.8 g/m3 * 100m3 * 0.3 = 174 g/h.

This means 0.174 l would be introduced from the outside environment into our room per hour and would have to be allowed for. When you extrapolate that across a day you’d be looking at >4 l so you can see why it’s an important factor, especially if your storing sensitive materials or objects.

Some applications demand very accurate extraction rates and therefore you must also consider internal sources of moisture. For example a single pot plant can add 150ml of moisture over an average 24hr period, which is already beyond the extraction capabilities of Peltier devices. However, pot plant pale in comparison to the most common source of additional water; people.

The average person will give off 50 ml of moisture per hour during sleep, rising to 70 ml for minimal activities and in excess of 100 ml for just basic household activities.

To get the best ROI from your dehumidifier it is essential to take into account all sources of moisture ingress. For example having got this far through this information you can see buying a Peltier dehumidifier would be pointless to eliminate condensation in a bedroom, after all two adults sleeping 8 hours will contribute something like 800 ml of moisture alone, and most Peltier devices have a maximum extraction rate of 300 ml per 24 hours.

If we go back to activities and look at other basic house hold activities such as cooking and showering, which can add 2 and 2.5 litres respectively to a room it’s pretty obvious that for the vast majority of dehumidifier activities you’ll probably need a refrigerant unit. It also helps illustrate the need to allow for additional capacity when specifying a dehumidifier, just like when you plan building work you have a contingency budget, as something unexpected always comes up!

Application suitability table

| Which Application?

| Condensation

| Desiccant

| |||

| Refrigeration

| Granules

| Desiccant Wheel

| |||

| Peltier

| Air Circulation

| Hot Gas

| |||

| Small spaces such as cupboards (under 10m3)

| R

| S

| S

| R

| S

|

| Rooms with 0°-8°C ambient temp

| –

| –

| –

| –

| R

|

| Rooms with 5°-35°C ambient temp

| –

| –

| R

| –

| S

|

| Rooms with 15°-35°C ambient temp

| –

| R

| R

| –

| S

|

| Construction

| –

| C

| C

| –

| C

|

| Flood damage

| –

| –

| C

| –

| C

|

Key: R= Recommended. S= Suitable. – = Unsuitable. C= Commercial/industrial types only.

Well, that just about concludes the basic introduction into the various types of dehumidifiers, how they work and their suitability. If you’re still scratching your head and still want to talk to someone then please do not hesitate to call us on 01527 830610 or email sales@broughtoneap.co.uk where a member of our expert team will be able to help.

For full details on our range of industrial dehumidifiers, portable air conditioning units, large fan heaters, evaporative coolers, ventilation fans, negative pressure units, portable electric boilers and everything else please see our site.