Does Broughton EAP LTD supply desiccant dehumidifiers?

During a recent program on Japanese cooking I was introduced to shokunin. This, in very basic terms, is the concept of speciality where chefs specialise in just one thing, like tempura for example. By specialising in just one thing it allows the chef to focus all their time, energy and concentration on doing that one thing the very, very best it can be done, rather than spreading themselves across a variety of disciplines, as with a more traditional approach.

Here at Broughton it all started with refrigerated dehumidifiers for us, we’re a refrigeration engineering company and with our 40 years’ experience we, just like the shokunin chefs who also study for decades, like to think we’ve got pretty good at it. It’s something we know and forms the foundation of our product range, so rather than spread ourselves too thinly we feel it’s probably best if we leave desiccant’s to desiccant specialists.

However, it’s also true that we’re a company that makes drying equipment and simply because of that we get asked about desiccant dehumidifiers; what they are and how they compare to their refrigerated cousins. With all that in mind we thought we’d put together a little section here on the website to look at the similarities, differences and most appropriate applications for the two types of commercial dehumidifier.

What are the differences between refrigerant and desiccant dehumidifiers?

It stands to reason that an informed purchase is a better purchase, right? Well, that’s what my mum’s always told me anyway and she’s usually right. So, with that in mind let’s see if we can shed a little light on the key differences, similarities and most suitable applications for both refrigerated dehumidifiers and desiccant dehumidifiers, so if you’re in the market for commercial drying equipment this section might well be worth a read, just in case it helps.

How do refrigerant dehumidifiers work?

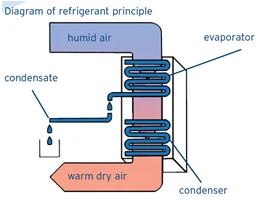

You know how sometimes you get up in the morning and there’s condensation on the bedroom window? Well that’s the same process a refrigerated dehumidifier uses to extract moisture from the air, because when air comes into contact with a cold surface the moisture contained within it condenses onto that surface.

Just like the fridge in you kitchen a dehumidifier contains a compact refrigeration system, but unlike the one keeping your milk cold which chills a set volume of air within an enclosed space the dehumidifier is designed to circulate the air in a room using a fan. Thanks to the low boiling point of refrigerant gasses the evaporator coil in your dehumidifier is now the coldest point in the room which means it becomes the ‘bedroom window’ mentioned above and any air drawn across it by the fan will leave it’s moisture on the fins of that coil. After that the moisture is collected in a tank or pump for disposal.

Incidentally, the processed water collected by dehumidifiers is a form of deionised water and is useful for applications such as steam irons or topping up the batteries in forklift trucks. Please note though that it might not be totally deionised and therefore shouldn’t be used for anything where that is critical.

The final part of the process air goes through in a refrigerated dehumidifier before being returned to the environment, is that it is passed across the condenser coil; the warm part of a refrigeration circuit, to be heated slightly and dispersed as warm, dry air.

How do desiccant dehumidifiers work?

Ever unpacked a new purchase and found a little packet of something that sounds and feels like salt in the bottom of the box? Well, that’s not salt it’s silica gel and it’s highly toxic so you really shouldn’t sprinkle it on your chips. Silica is a desiccant which means it absorbs water and the reason its there is to protect the thing you’ve just bought from any damage that could be caused by moisture.

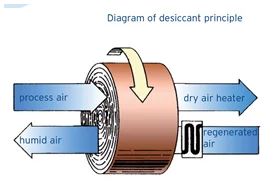

Now, as you’ve probably already guessed, desiccant dehumidifiers use moisture-absorbing substances such as silica to dry air instead of the refrigeration circuit we mentioned before. Because they don’t rely on refrigerant gasses or cold surfaces desiccant dehumidifiers can operate in much lower ambient temperatures than their refrigerated cousins. They are also particularly well suited to applications where very low relative humidity (more commonly known as the RH level) is needed, a low dew point (the technical term for the temperature at which the moisture within the air condenses) is essential, or for when the unit has to be ducted into the area that needs drying.

These days the majority of desiccant dehumidifiers house the desiccant material in a ‘wheel’ which rotates. These wheels or rotors as they are also known combine alternating layers of flat and corrugated sheets impregnated with the active component (desiccant). What this does is create a huge number of axial air channels running parallel to each other through the rotor structure. As air is drawn through these channels, moisture is transferred from the air to the desiccant.

An industrial application is where a specific RH level or large reduction in moisture content is required it isn’t unusual to see both refrigerated dehumidification and desiccant drying used in conjunction with each other. In these processes the pre-cooling will be done via a refrigerated circuit before the air is passed through a desiccant system to carry out further moisture removal.

Major components of both types

We’ve already covered refrigeration systems to an unread-ably dull level of complexity elsewhere on the site, but as a commercial site dehumidifier sits right at the most basic end of the spectrum the primary components to make one up are relatively few:

A fan to circulate the air

A compressor to circulate the refrigerant around the enclosed system

A ‘combi’ coil that is made up of both the evaporator and condenser coils.

Whereas with the slightly more complicated desiccant dehumidifier there are usually five major components:

The rotor which houses the desiccant.

One fan to draw air (aka the process air) into the unit.

A heat source used to regenerate the desiccant (I think that’s a fancy way of saying ‘stop it getting saturated and therefore ineffective’).

Another fan to draw the heat through the rotor.

And finally, as the name rotor suggests – the rotor has to rotate, albeit very gently. In order to this some sort of mechanical devise like a motor is also needed.

Desiccant dryers can process large volumes of air, up to 5,500m³/hr and they can also feature a range of ancillaries such as particulate and oil-removal pre-filters, automatic condensate drains and an after-filter that cleans outlet air down to as small as 0.01 micron. Depending on who you get them from you might also need to get the necessary control instrumentation and for these operations, especially if you plan on matching them with air compressors and after-coolers, together or separately, for a comprehensive drying solution.

Which dryer should I use, and when?

Refrigerant dehumidifiers are best suited to building sites where they get used to speed up the drying of plaster of concrete so other trades can get in and carry out their work. Refrigerant units are well suited to this type of scenario as they help ensure the delicate drying process is carried out without surfaces cracking or shrinking before the composite has set properly.

On the other side, desiccant dehumidifiers will be typically found in applications where very dry conditions are essential – usually in the pharmaceutical and petrochemical industries – because they can provide much lower levels of humidity. They’re also often used for applications where access is restricted to the area that needs drying out, areas like storage tanks or marine environments for example.

For details on our full range of site dehumidifiers, portable air con units, large fan heaters, portable ventilation fans, cooling fans, portable got water packages, fan coil units etc, please visit our website or call 01527 830610 where a member of our team will be happy to take your call.